product &

performance testing.

Access our in-house testing capabilities and specialised team to manage all aspects of device validation — from mechanical performance to packaging, sterilisation, and biocompatibility.

Actis Medical offers full-service validation to meet all relevant ASTM and ISO standards. Our NATA-certified equipment and regulatory experience ensure your device meets global expectations for safety, durability, and performance — with testing aligned to regulatory requirements.

Our experience includes

- Mechanical testing — fatigue, wear, subsidence, tensile, compression, and torque testing for implants and fixation (hip, knee, spine, trauma, sports medicine)

- Biocompatibility testing — full test planning and execution, including regulatory-ready Biological Evaluation Plans and Reports in line with ISO 10993

- Cleaning, residuals, and sterilisation validation — for Gamma Irradiation and Ethylene Oxide (EO)

- Accelerated and real-time ageing — access in-house services to simulate shelf life and enable full packaging validation

- Packaging system validation — including seal strength, integrity, and distribution simulation in compliance with ISO and ASTM standards

- Usability and simulated use testing — to support clinical safety, performance claims, and regulatory expectations

- Magnetic Resonance Imaging (MRI) safety testing — including torque, displacement, and artifact assessment

Product Development

Engage with our design engineers to take your product from concept through the design and development process ready for manufacturing.

Read more

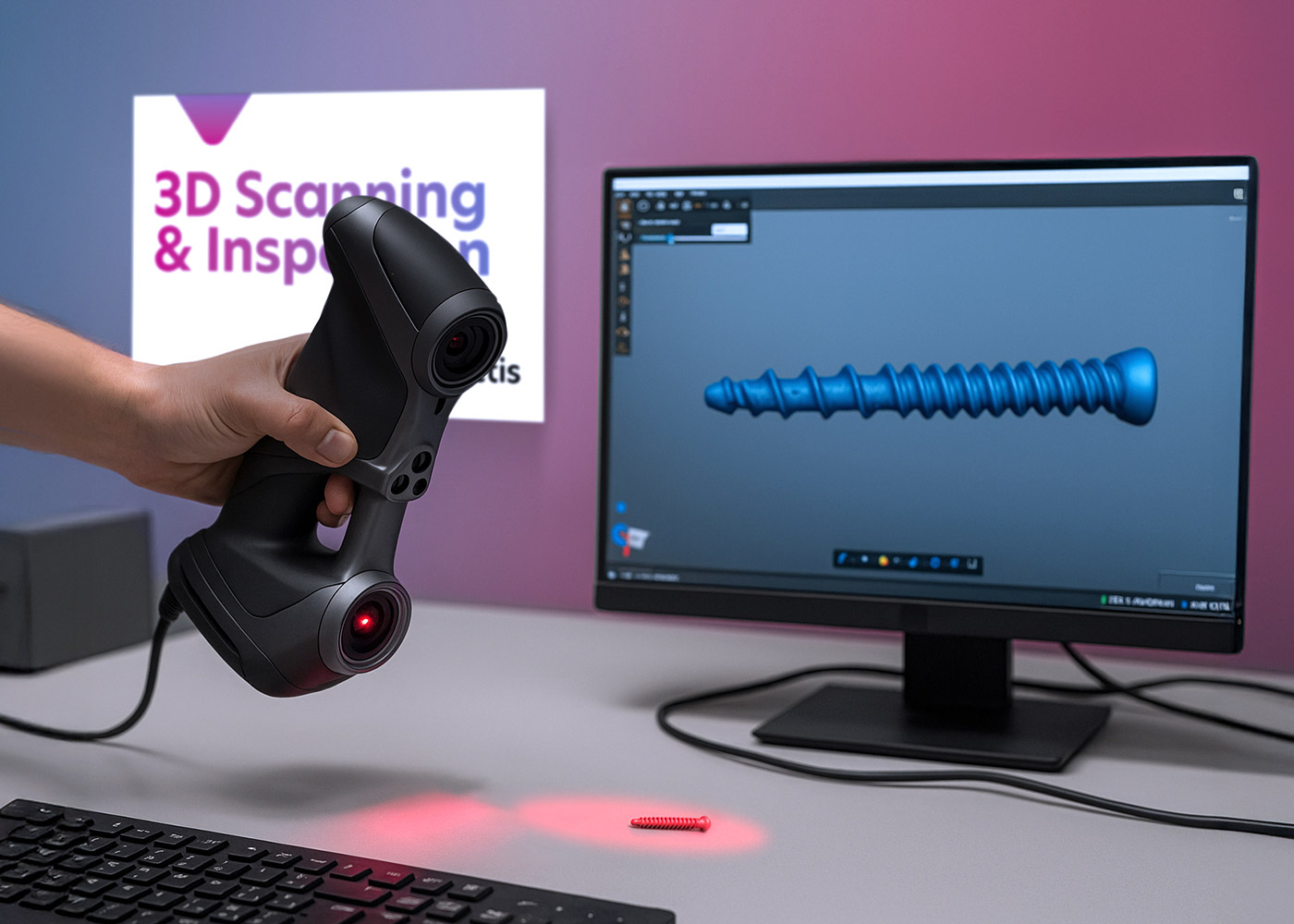

3D Scanning & Inspection

Access high-accuracy 3D scanning and inspection services to accelerate design, reverse engineering, and development. Ideal for implants & instrument design,...

Read more

Manufacturing

Transform your design concept from prototype into a market ready product using appropriate manufacturing methods. We offer contract manufacturing which...

Read more

Quality and Regulatory

Quality & regulatory solutions from specialist advice to full execution so you can focus your time where it matters most....

Read more

3PL / 4PL Logistics

Actis offers comprehensive third-party (3PL) and fourth-party (4PL) logistics services — managing everything from warehousing and distribution for your devices...

Read more