manufacturing.

Transform your concept into a market-ready product with Actis Medical — leveraging

in-house additive manufacturing, sterilisation and ISO 13485-certified capabilities to

deliver high-quality, compliant medical devices.

- Comprehensive in-house manufacturing supported by a trusted global vendor network — enabling scalable sourcing, production, and integrated supply chain support, all managed under our ISO 13485 quality system

- Access our in-house 3D printers to rapidly produce patient-matched devices — including surgical guides, anatomical biomodels, and implants

- Access validated sterilisation processes including Ethylene Oxide (EO) and Gamma Irradiation — strengthened by our in-house EO capabilities for improved speed, control, and integration with your production timeline

- Cleanroom packaging design and assembly — including sterile barrier systems (pouches, blisters, and cards) and fully validated workflows

- Contract manufacturing and private label manufacturing for high-risk and sterile medical devices — including single-use, implantable, and reusable devices

Extensive manufacturing experience including:

- Orthopaedic implants and sterile consumables — from plates, screws, and arthroplasty implants to sterile consumables such as drills, pins, guidewires, and arthroscopy devices

- Patient-matched 3D printed devices — including anatomical biomodels, surgical guides, and implants tailored to individual anatomies

- Surgical instruments & kits — designed across multiple specialties including colorectal, gastro-urological, and spinal denervation procedures

- Active non-implantable devices — including electronic communication systems used in cardiovascular applications

- Infusion and delivery systems — including subassemblies and components for fluid and medication management

Product Development

Engage with our design engineers to take your product from concept through the design and development process ready for manufacturing.

Read more

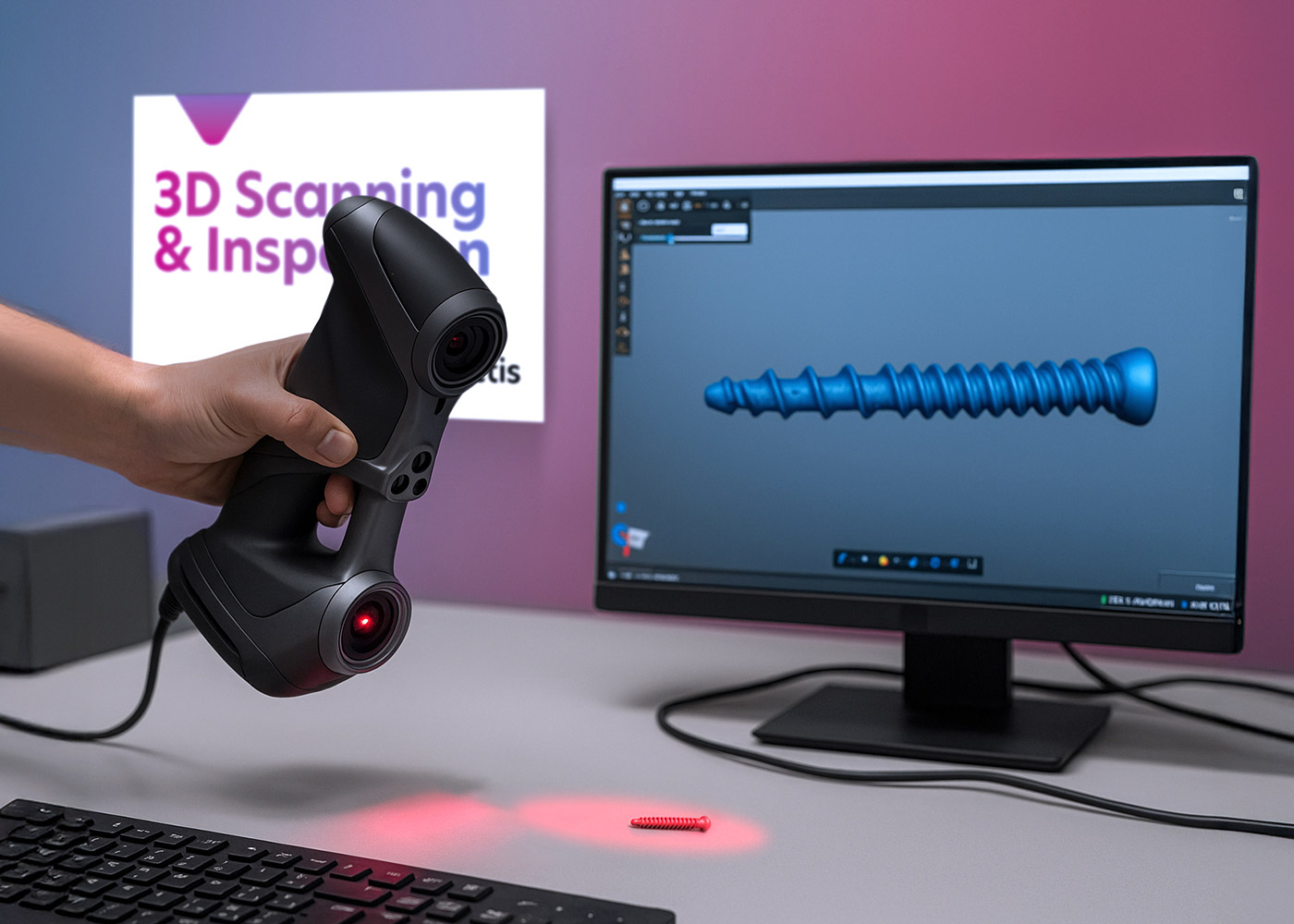

3D Scanning & Inspection

Access high-accuracy 3D scanning and inspection services to accelerate design, reverse engineering, and development. Ideal for implants & instrument design,...

Read more

Quality and Regulatory

Quality & regulatory solutions from specialist advice to full execution so you can focus your time where it matters most....

Read more

Product & Performance Testing

Regulatory Authorities such as the TGA and FDA require comprehensive performance data to approve a medical device application. Actis Medical...

Read more

3PL / 4PL Logistics

Actis offers comprehensive third-party (3PL) and fourth-party (4PL) logistics services — managing everything from warehousing and distribution for your devices...

Read more